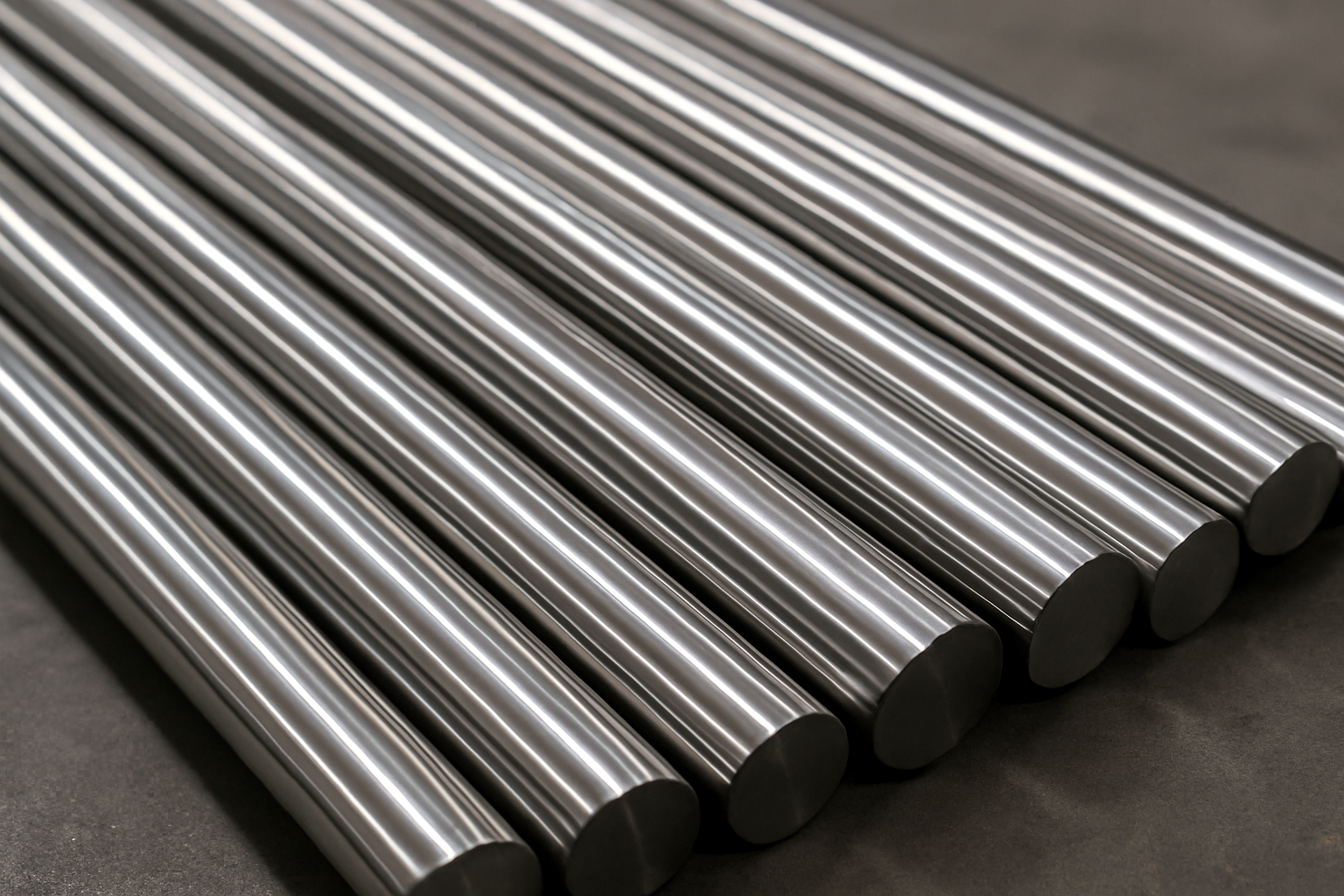

We finish stainless and alloy bar stock to your specified Ra, gloss, or visual standard—ready for downstream assembly, coating, or end use. Learn more about our full capabilities on the

homepage.

What Our Polishing Delivers

- Target finishes: fine matte to bright polish, per print or Ra requirement

- Defect reduction: minimizes light scratches, handling marks, and surface artifacts

- Dimensional control: controlled stock removal to maintain diameter tolerance

- Uniform appearance: consistent grain direction and sheen along full length

Capabilities & Process Controls

- Polishing for round bars, rods, and cut pieces

- Stainless steels, carbon/alloy steels, and select specialty alloys

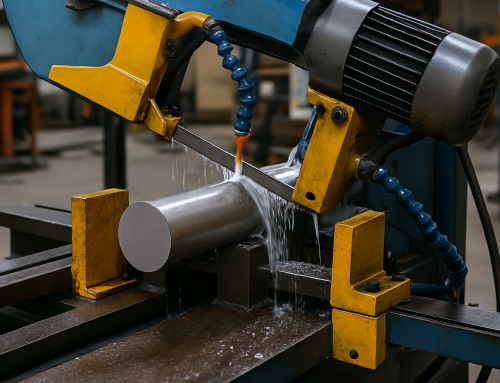

- Progressive abrasive sequences for repeatable finishes

- Coolant, speed, and pressure control to protect metallurgy

- In-process inspection for diameter, runout, and visual criteria

Polishing can be paired with centerless grinding, straightening, saw cutting, and chamfering for a complete, ready-to-use bar product.

Typical Uses & Industries

Polished bars are common in applications where appearance, cleanliness, or low friction matter:

- Medical, food, and pharmaceutical equipment

- Architectural and aesthetic components

- Linear motion shafts, guides, and pins

- Instrumentation and precision assemblies

Why ES Precision Metals?

- Tight integration with upstream machining and finishing

- Repeatable finishes across batches and releases

- ISO-driven quality checks and documentation on request

- Responsive quoting and dependable lead times

Contact & Location

Ready to specify your finish or request a quote? Visit our

homepage or the

Polishing page.

Address:

6530 S. Laramie Ave

Bedford Park, IL 60638

USA