What Is Bar Chamfering?

Chamfering is the machining or finishing operation that removes sharp edges from the ends of bars or rods by creating a beveled or angled transition between two surfaces. A chamfer may be flat (commonly at 45°), or modified per design needs. In metalworking, chamfering serves both functional and safety purposes.

Learn more.

- Burr removal and eliminating sharp edges

- Easier insertion into mating parts or assemblies

- Preventing damage to adjacent components

- Improving handling safety and component aesthetics

Specialized chamfering is especially critical when tight tolerances, high repeatability, or high-speed machine compatibility is required, such as in aerospace, medical, or precision manufacturing settings.

Our Capabilities & Process

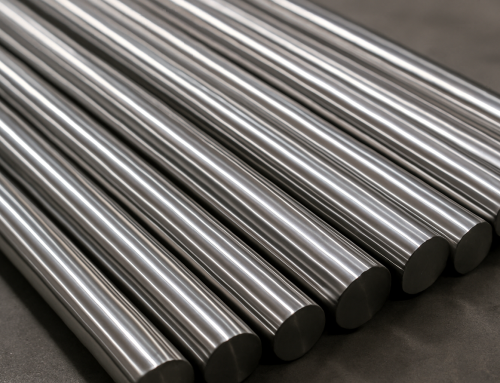

At ES Precision Metals, we integrate bar chamfering seamlessly into our broader precision bar services, leveraging our expertise in ground, turned, and polished steel and stainless steel bars. Visit our

homepage to learn more.

- Chamfering round bars and rods of various diameters

- Custom chamfer depths, angles, or radii per drawings or specifications

- Precision control to maintain uniformity across batches

- Integration with centerless grinding or other finishing operations

We apply rigorous quality control measures to ensure every chamfer conforms to tolerance and finish requirements. Our in-house metallurgist and QA team further confirm that the chamfered ends meet mechanical and metallurgical integrity standards.

Applications & Industries

Bar chamfering has broad applications in many industries, including but not limited to:

- Aerospace and defense

- Medical devices

- Automotive and precision machinery

- Tool and die manufacturing

- General industrial components

Why Choose ES Precision Metals?

When you partner with ES Precision Metals for bar chamfering, you benefit from:

- Deep expertise in precision bar fabrication and finishing

- High standards of quality backed by ISO 9001 and internal lab testing

- Ability to integrate chamfering with grinding, polishing, and other value-added services

- Updated production capability and technologies to support high volumes and tight specs

- Responsive quoting and customer support

Contact & Location

For inquiries or to request a quote on bar chamfering, please visit our

homepage or directly submit a quote request through our

Bar Chamfering page.